Sheffield Razor Steel

I have often wondered how the steel for our antique razors was made, and perhaps why some old razors appear to have an individual or special ‘feeling’ about them. Does the answer lie in their method of manufacture and the effort that went into making their steel?

What I have discovered is that the manufacture of steel in 1800 was a complicated and very imprecise process – a Black Art in which secret knowledge and recipes were passed from master to apprentice over many generations. These highly skilled iron masters did not have the benefit of our science or technology. They worked entirely by feel, intuition and experience, and their recipes might have been “a bucket and a bit of this plus a handful of that, heated until it looks and smells right”, but these were clever men and their steel was turned into perhaps some of the finest razors ever made. It is thought provoking that our very old razors still hold the long-lost secrets of these masters.

To keep this account as concise as possible, I will focus on the steel produced in England specifically for razors before 1860 and used by Sheffield and London’s ‘little mesters’ – before the era of huge cutlery works and large steelworks. After this period, rapid advances in the science of metallurgy allowed the composition of steel to be better understood and steel to be manufactured consistently to ever more specific recipes tailored to its end use, and in ever increasing quantities and quality for the industrialised world, but the principles mentioned here remained the same.

So, what is steel? It is primarily an alloy of iron and carbon, but with additional minerals that can improve or degrade the performance of the final product. These minerals are either present in the naturally occurring iron or nowadays can be added during manufacture. The early iron masters were unaware of these minerals, and so relied on the properties of the iron that they could obtain. Steel production has been traced back 2000 years in China and India, but their methods were very basic and they could only make it in very variable quality and in small batches at a time.

The fundamental problem of making steel for razors is to carefully control its carbon content. Too much carbon and the metal is hard but brittle, too little carbon and the metal is too soft to take an edge. With modern analysis, we now know that a carbon content ranging from approximately 0.8 to 2% by weight gives the perfect properties required to make razors. But of course, the early iron masters could only produce this quality steel from years of experience of which methods and recipes worked and which didn’t.

Iron is the most abundant metal on earth. It exists in various forms naturally throughout the world and is called iron ore (an oxide of iron – like rust and is sometimes called ironstone or iron sand).

The Wide Variety of Iron Ore

Iron ore was produced by volcanic activity additionally contains a cocktail of other minerals which are difficult to remove and yet affect the properties of the finished steel, importantly this cocktail of minerals in the ore varies throughout the world. British iron ore contains sulphur and phosphorus, both of which reduce the performance of the finished steel whereas Swedish iron ore does not contain these minerals but contains beneficial minerals such as Vanadium and Manganese (more later).

Smelting is the process by which metallic iron is extracted from iron ore. It was quickly discovered that charcoal was the best fuel to produce the very high temperatures necessary to smelt iron ore. Hence, during this heating process, the charcoal inevitably mixed with the iron ore and produced a honeycomb like, spongy, red hot mass of relatively pure iron. Intermixed with unwanted bits of the charcoal and other materials (generally known as slag). We now know that the carbon releases oxygen from the iron oxide to produce iron and carbon dioxide. The separation of slag from the iron is aided by the addition of flux, that is, crushed seashells or limestone. The formation of this bloom of metal was as far as the primitive iron smith got: he would remove this spongy mass from the fire whilst it was still red hot and hammer it to drive out the cinders and slag (seen as sparks) and to compact the spongy metallic particles into a solid mass.

This bloom of metal was called wrought iron (“wrought” means “worked,” that is, hammered) and it generally comprised 0.02 to 0.08 percent of carbon, just enough to make the metal both tough and able to be beaten or forged into shape, but not able to form or hold a decent cutting edge. The big problem with this method was that only very small batches of metal could be made (perhaps for one sword), and the world was becoming hungry for iron to make cannon, swords, armour, nails, tools etc.

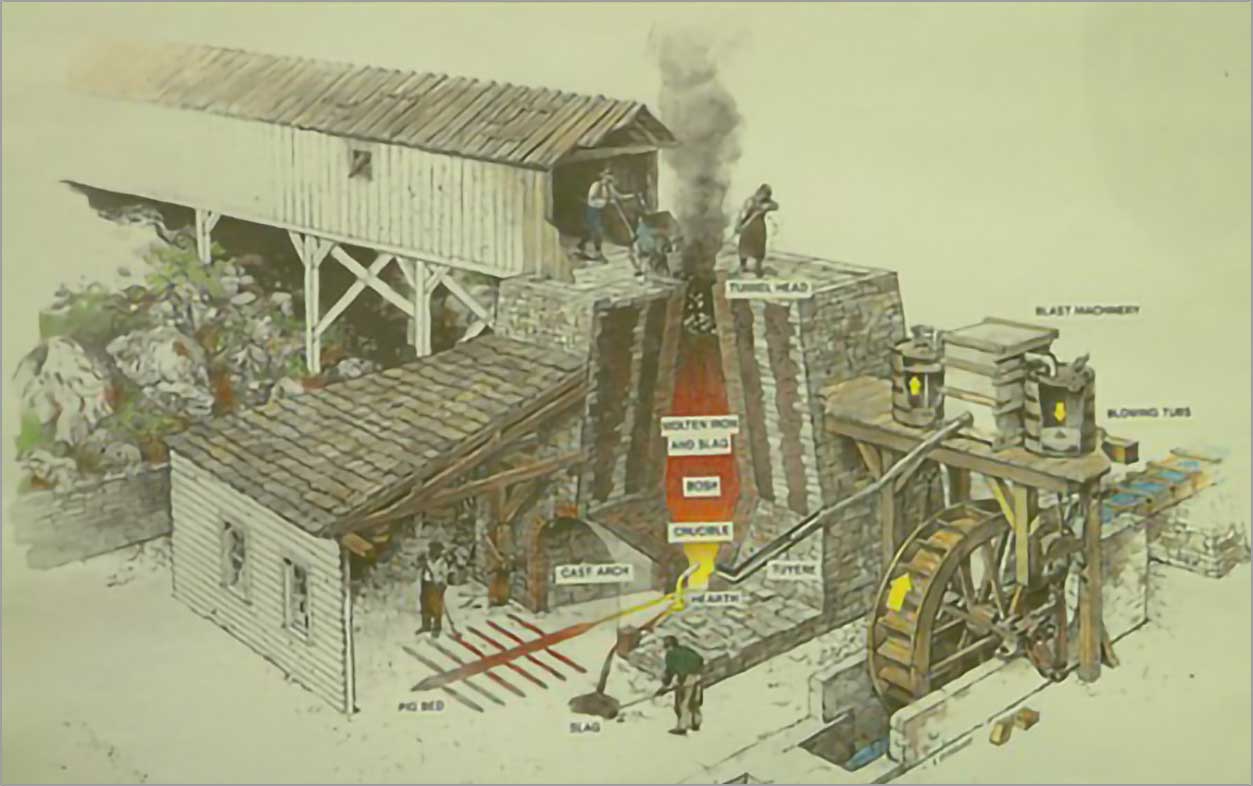

At some time during the Middle Ages, it was discovered that at very high temperatures (we now know at about 1200 C) iron ore begins to produce molten metallic iron. We also now know that at these temperatures the iron absorbs large quantities of carbon from the charcoal. The result is called cast iron and it contains from 3 to 4.5 percent carbon by weight. This high proportion of carbon makes the metal hard but brittle; it is liable to crack or shatter under a heavy blow, and therefore it cannot be forged. By the 16th century, European ironmakers had developed the blast furnace to be able to achieve these high furnace temperatures and therefore were able to produce molten cast iron in relatively large quantities.

The furnace was loaded with alternating layers of charcoal, flux, and iron ore and the combustion of the charcoal was intensified by a blast of air pumped through the mixture. This could be a continuous process as more ingredients were added at the top as the iron ore and charcoal were converted into iron and tapped from the base.

Early ironworkers used water wheels to power the bellows to pump air through the blast furnace; after 1777, James Watt’s new steam engine was increasingly used for these purposes. Molten cast iron would run directly from the base of the blast furnace into a sand trough which fed a number of smaller lateral troughs; this configuration resembled a sow suckling a litter of piglets, and cast iron produced in this way came to be called pig iron. Pig iron could be cast directly into moulds at the blast furnace base or re-melted elsewhere to make cast iron stoves, pots, pans, fire backs, cannon, cannonballs etc (“to cast” means to pour into a mould, hence the name “cast iron”). Casting is also called founding and is done in a foundry.

So, we now had two forms of the metal – brittle cast iron with too much carbon and soft wrought iron with not enough carbon for razors, we needed something in the middle. And we also needed it in increasing quantities as the population in Britain was growing rapidly (1760 – 6 million, 1850 – 21 million)!

But, only cast iron could be produced in large quantities and so a second refining process was developed to remove the carbon and convert cast iron into the more useful wrought iron. This involved heating cast iron bars to red/white heat in a charcoal furnace and then hammering them to remove impurities and oxidise excess carbon. This was done in a finery forge and became known as the Walloon method from the (Belgian) people that developed it (this was used well into the 19th century). But this process could still only produce relatively small batches of wrought iron until1784 when a puddling furnace was developed by the Englishman Henry Cort.

The puddling furnace kept the molten metal separate from the charcoal and required stirring the molten cast iron through an aperture by a highly skilled craftsman called a puddler; this exposed the metal evenly to the heat and combustion gases in the furnace so that the carbon could be oxidized out. A similar process was also developed called the Lancashire Hearth process. During these processes, as the carbon content decreases, the melting point of the iron rises, causing semi-solid bits of iron to form in the liquid mass. The worker would gather these into a single mass, remove it and then work it under a forge hammer to remove the remaining impurities and so produce wrought iron. We could now produce wrought iron on an industrial scale.

So, by the late 18th century, blast furnaces were used to produce large quantities of cast iron from iron ore and charcoal (or latterly coke) and then coal fired puddling furnaces were used to convert it into the more useful wrought iron. But we still didn’t have steel with the optimum carbon content for razors! We needed to add carbon to the wrought iron before we had razor steel.

This was carried out by the cementation process. Bars of wrought iron would be packed with a carefully controlled quantity of powdered charcoal, layer upon layer, in tightly sealed stone boxes and heated to red heat. After cooking for several days, the wrought iron bars would have absorbed the carbon in the charcoal; to distribute the carbon more evenly, the metal would be broken up, re-bundled with charcoal powder, and reheated. The resulting blister steel would then be heated again and brought under a forge hammer to give it a more consistent composition.

But blister steel still did not make ideal razors. By chance, in the 1740s, the English clockmaker Benjamin Huntsman, searching for a higher-quality steel for making clock springs, discovered that blister steel could be completely melted at very high temperatures (we now know about 1500 C) in clay crucibles and further refined by the addition of a special flux (e.g. sand, glass, ashes) that removed the remaining fine particles of slag that the cementation process could not remove. This was called crucible or cast steel; by carefully controlling the process it was discovered that this could have just the right amount of carbon for making razors, but it could only be made by hand in very small quantities and was thus very expensive. Early, high quality razors were often stamped “cast steel” to show that they were the best that money could buy.

Casting a crucible full of molten crucible steel

Abbeydale (part of Sheffield) crucible furnaces built in about 1830

Clay crucibles waiting outside the furnace

I haven’t yet mentioned the variability of iron ore. Iron ore exists in great quantities throughout the world, but it was found that the British ore did not make good razors (we now know that it had too much sulphur which makes the blade prone to chipping). By a lengthy process of trial and error it was found by the 16th century that iron from Sweden was the best for refining into steel that would take a durable edge. We now know that it contained no ‘bad’ minerals and many ‘good’ minerals such as manganese which aids the final hardening process of the razor’s edge. Therefore, Sweden became a major supplier of cast iron to England. In fact, in the 18th century almost half of the Swedish output of wrought iron came across the North Sea to England (average about 20,000 tons per year). We also imported a similar quantity of wrought iron from Russia, but this was of only of similar quality to British iron and was useless for making good razors.

For hundreds of years the Swedish iron industry was tightly controlled by the Crown – the source iron foundry and the iron quality had to be proven before each ingot could be stamped with the details and exported. And there were various qualities of Swedish iron too – there were hundreds of mines, but the very best iron came from the Dannemora mine and shipped via the nearby port of Öregrund (it was often referred to in England as oregrounds iron).

The English trade in oregrounds iron was controlled from the 1730s to the 1850s by a cartel of merchants, of whom the wealthiest and longest enduring members were the Sykes family of Hull. Other participants were resident in (or controlling imports through) London and Bristol. These merchants controlled the prices and advanced money to Swedish exporting houses, which in turn advanced it to the ironmasters, thus buying up the entire output from the best forges for several years in advance – and preventing other countries from acquiring large quantities of this precious metal (for armaments).

So, in early 19th century England, razor quality steel had a long journey: in Sweden, iron ore was first mined and then smelted in blast furnaces to produce cast iron which was then refined into wrought iron by the Walloon process (later by puddling or the Lancashire Hearth methods). It was then imported into Britain (Hull being the incoming port for Sheffield as it provided river/canal access to Rotherham and then by road to Sheffield – later, it was possible to barge iron directly from Hull to Sheffield). The wrought iron was then refined in cementation furnaces to produce blister steel which could be used to make razors or was further refined in a crucible furnace to produce the finest quality crucible steel for the very best razors.

We should remember that all of these processes were carried out without the benefits of science and technology. Temperatures were judged by eye and even ear; the correct quantities of carbon and fluxes to add were known from experience handed down through generations of iron masters and adjusted by the ‘feel’ of each individual batch. The masters guarded their knowledge, and each master’s steel would have been slightly different from another’s because his fluxes were known only to him and his methods were kept secret. Yes, there was national and international industrial espionage even in those times! Even an individual iron master’s steel would vary slightly from batch to batch.

Our little mester therefore had a variety of iron masters to buy his steel from. Each razor smith would have had his own trusted source because he knew how to work it and the results that it would give. The very best crucible steel was very expensive because it had been through many stages of refining – but it could produce superlative razors. Cheaper razors used cheaper, less refined blister steel coming from lower grade iron ores. Razor apprentices would learn all of this from their masters, who had learnt it from their masters, who….. As you can see, this was a very complex and highly skilled process that evolved over hundreds of years and came to a peak in the early 1800s.

So, our very old razor is the product of this long and complex international chain of events involving many highly skilled men who worked with their hands and their brains and had mastered their specialist arts over many years. Is this what makes each razor special and different – possibly – or was it also the final heat-treating process that the razor master used? More of this another time.

Endnote

The mass-production of cheap steel only became possible in the latter part of the 19th century after the introduction of the Bessemer process which quickly converted large quantities of cast iron directly to steel with a carefully controlled carbon content. This was named after its inventor, the British metallurgist Sir Henry Bessemer (1813-1898). By the latter half of the 19th century, Britain was producing half of the world’s iron. This spelt the demise of the little mesters and the old London cutlery businesses and opened the way for ever larger mass production cutlery ‘works’ in Sheffield such as Rogers or Wostenholm. They had direct access to the local coal fields and steel works and could produce consistently good razors in large enough quantities to export all over the world, making their owners extremely wealthy in the process.

“Articles By Eric Gilroy”

Quick Contact

+44 (0)7557385501

Edge Dynamics, PO Box 673, Greenford, UB5 9SE, UK

Why Edge Dynamics?

We are passionate about honing straight razors to produce only the smoothest, sharpest edge possible. At Edge Dynamics, we offer you first-class, personal honing that includes all finishing touches and a properly stropped edge.

We Accept | PAYMENT OPTIONS