James Johnson

This story transports us back to Sheffield of the mid 1800s and gives us a glimpse of how one of the many honest razor smiths and their families lived and worked.

James was born in 1803, probably in the early cutlery producing area of Sheffield called Attercliffe, the son of a cutler – James Johnson, who was the son of a cutler James Johnson. Both being time served apprentices in the trade and therefore would have been made Freemen of Sheffield.

There are no records of our James, or any of his sons, serving an apprenticeship, so perhaps his skills were passed down through his family. In those days, a family had to pay the Master a good sum of money to train their son, who had to live with the Master. After 1814, the rules for cutlery apprenticeships in Sheffield were relaxed, and so it is probable that James was able to learn his skills from his father. He would have begun his formal ‘apprenticeship’ when he was 14 and completed it in 1824 as soon as he became 21 (although he may well have helped his father and grandfather in their workshop from a much earlier age).

In 1826 at the age of 23, James married 19-year-old Martha Martin on 26 October, in Sheffield. They remained married for the rest of their lives.

James only ever worked as a one-man concern from his home (probably with his son James as an apprentice), and so he was a typical ‘Little Mester’. Razor manufacture only needed a small blacksmith type workshop with a forge to heat the metal and an anvil to shape the blade. The blades were then ground to a fine edge on a series of grinding wheels. Little Mesters, working from home, would not have the steam or water power for their own wheel, and so James would probably have rented a wheel in a purpose-built grinding workshop on a daily basis – these large buildings were called Wheels. Often, these Little Mesters supplemented their own work with contracts from larger manufacturers or wholesalers.

Little Mesters in nineteenth century Sheffield, usually rented one or more troughs in one of the many wheels located throughout Sheffield. Each wheel consisted of rooms called hulls and each hull had a number of trows or troughs. The trough was made of cast metal and contained the water in which the grinding stone revolved. Each trough had divisions for the types of grinding stone – the glazer, the lapper and the polisher. In the back of the room was a drum or wheel, normally driven by a water wheel or latterly a steam engine, and wheel bands from it were used to drive either grinding stone.

Sometimes a Little Mester would sub-let troughs from a hull or sometimes he would rent a hull and employ apprentices to work in the other troughs.

Boys, often sons of Little Mesters, as young as seven or eight were employed in the Sheffield wheels and their young lungs were particularly susceptible to the dust from the grinding stones. They were usually employed in polishing and frequently suffered from coughing and shortness of breath. In this way, many families lost generation after generation to the trade – life expectancy could be as low as 30 years.

The photos below show a grinding hull of the 1820s, just as James would have used.

A typical hull might house about 6 grindstones for shaping and 2 glazing stones for finishing. The stones (made from sandstone) were 6 feet in diameter when new and hung in a trough filled with water to keep the stone wet when grinding. The grinder sat astride a wooden horsing over the stone and held the blade against the stone as it spun round.

Grinding was a dangerous occupation and grindstones could ‘burst’ injuring anyone nearby. Many grinders suffered from silicosis or ‘grinders disease’ through inhaling the stone dust, and so life expectancy was very low in this trade. To grind faster, water was often dispensed with – dry grinding, allowing even more stone dust to be inhaled.

James stayed in Sheffield all of his life, and did not move very often:

- 1828-1829 he was listed in Pigot’s Directory as a razor manufacturer in New Church Street

- 1833 he was listed in White’s Directory as a razor manufacturer in Fitzwilliam Street

- 1835 he was listed in Fitzwilliam street

- 1841 he was listed in Pigot’s Directory as a razor manufacturer in Fitzwilliam Street, and then Eyre Street

- 1849 he was listed in White’s Directory as a razor manufacturer 54 Broomhall Street & 66 Fitzwilliam Street

James and Martha had twelve children, many of whom led pitifully short lives:

- Lydia 1829 – died at birth?

- Samuel Benjamin 1830 -1851 aged 21

- Anne 1831 – 1880 aged 49

- James 1833 – 1889 aged 56 (Razorsmith, Ecclesall Union)

- Margaret 1835 – died at birth?

- William Edward 1836 – 1840 aged 4

- Mary Elizabeth 1838 -1839 aged 6 months

- George Wostehnholm 1838 -1851 aged 13

- William Henry 1841 – 1851 aged 10

- Robert 1842 -1886 aged 44 (Cutler, Back of 17 Bailey Street)

- Frederick 1849 -1894 aged 48 (painter, 22 Harrington Road

Sheffield General Cemetery Grave: DD 65

Mary Elizabeth JOHNSON, Infant, Fitzwilliam Street,Sheffield age: 6m, buried: 24 May 1839

William Edward JOHNSON Infant, Fitzwilliam Street,Sheffieldage: 4, buried: 8 Jul 1840

William Henry JOHNSON Infant, Eyre Street age: 10, buried: 26 Mar 1851

Samuel Benjamin JOHNSON, Eyre Lane age: 21, buried: 18 Apr 1851

George Wostehnholm JOHNSON Infant, Eyre Street age: 13, buried: 1 Feb 1851

Timothy JOHNSON Son of James Johnson, Razor Manufacturer, Grinder’s Hill, Paternoster Road age: 18, buried: 24 Sep 1868

James JOHNSON Manufacturer, Paternoster Row age: 66, buried: 31 May 1869

Martha JOHNSON Widow, 22 Harrington Road age: 80, buried: 14 Dec 1887

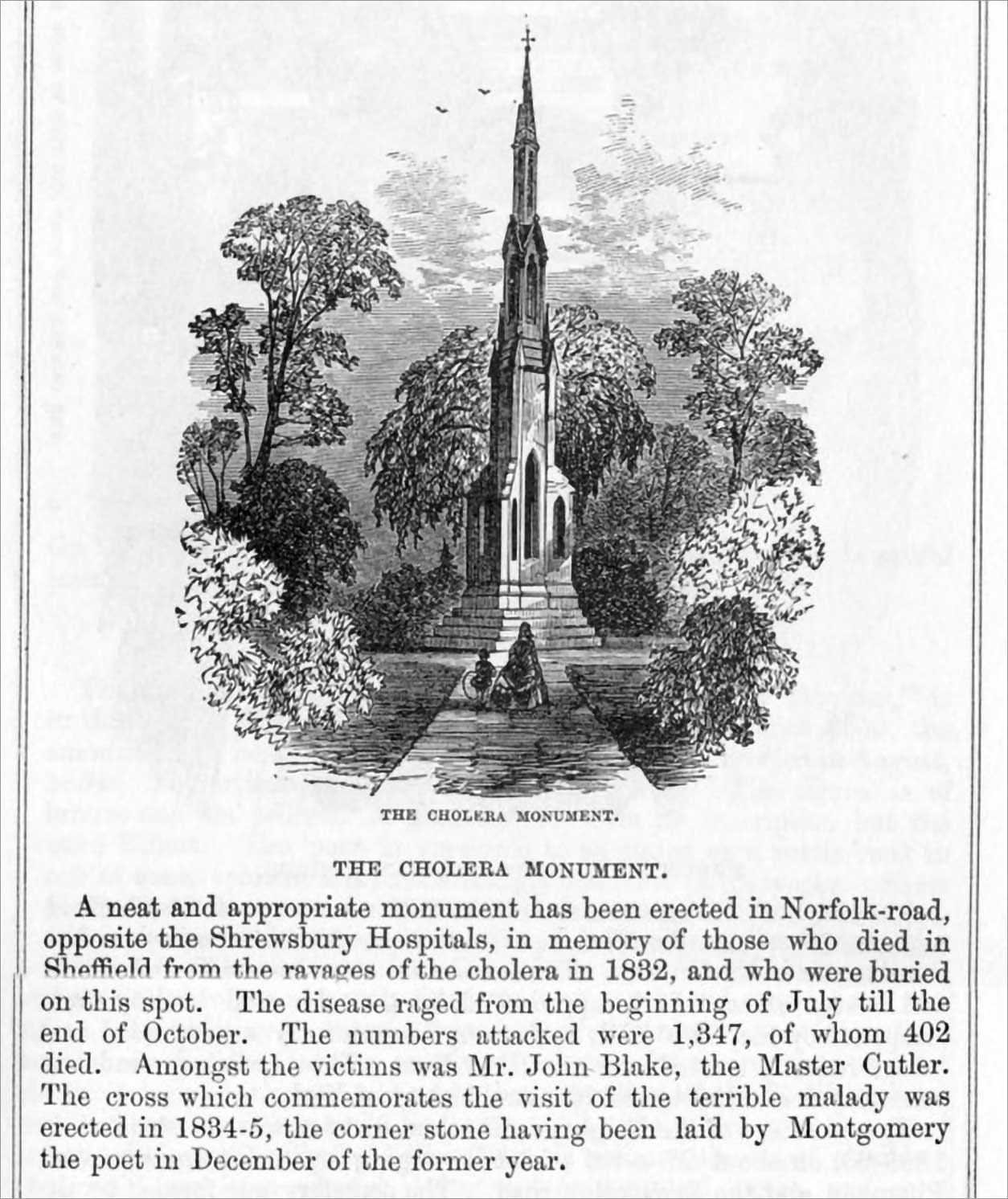

To add to the hazardous working conditions, there was a major Cholera outbreak in Sheffield in 1832 in which over 400 people died (about 1% of the population). This was caused by drinking water from local wells mixing with raw sewage. A note from Sheffield Mercury, 16 June 1832

“Cholera is likely to come to Sheffield. It attacks chiefly the dirty, the idle, the drunken and the disorderly”.

The authorities struggled to cope with the outbreak. There was a system of carrying away those infected to the workhouse on Kelham Street, the upper floor of which was given over to a ‘recovery house’. Those that succumbed were at first buried in parish churchyards but following complaints about bodies being carried through the streets on carts and having to live next to churchyards, it was decided to provide a hearse and an isolated burial ground at Clay Woods (near what is now Norfolk Park). There were further smaller outbreaks in 1849, 1854 and 1866.

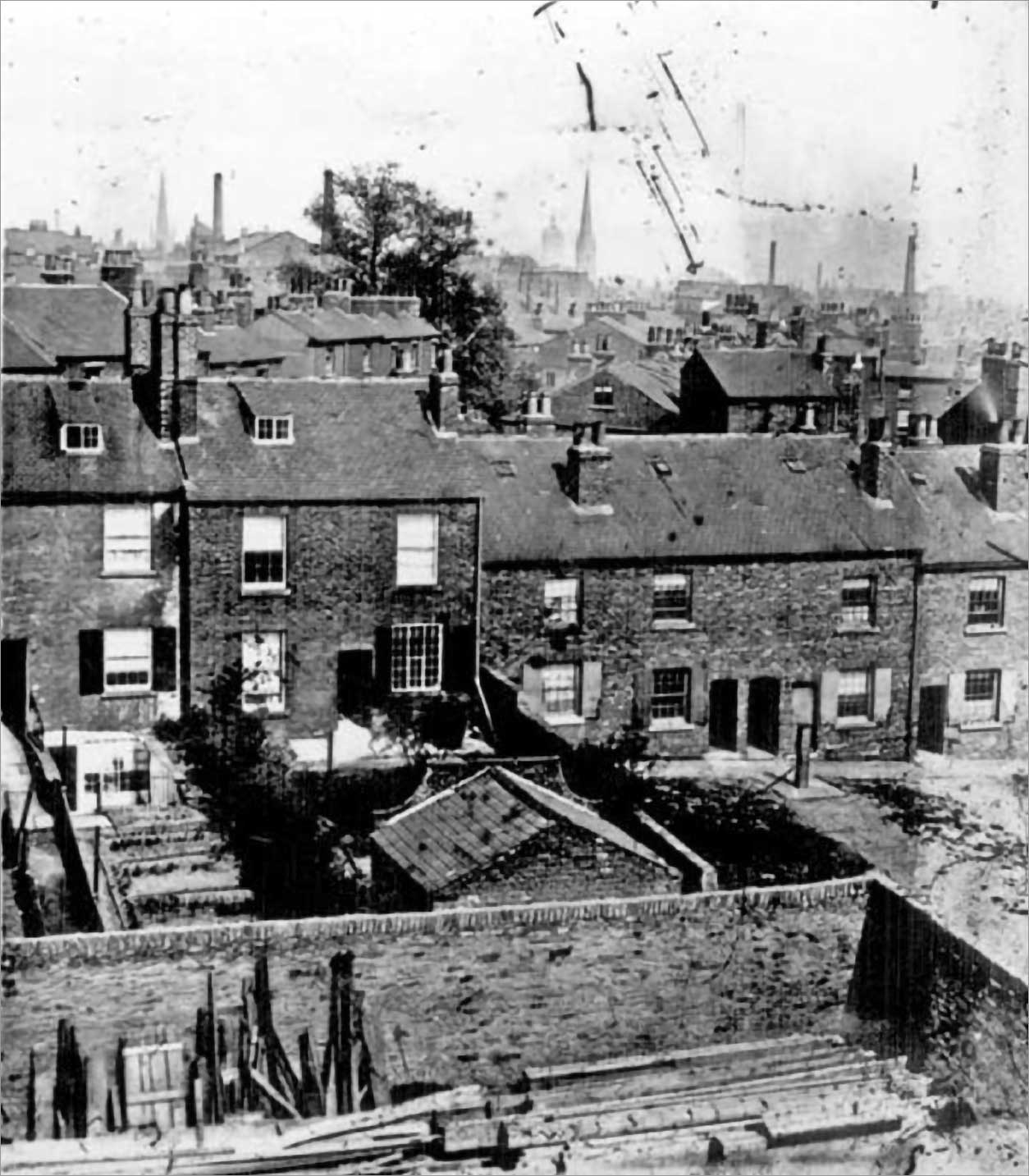

The back of Fitzwilliam Street where James first lived and worked. Note the communal water pump.

Typical back-to-back housing in Victorian Sheffield

Near where James later lived and worked

Patternoster Row – The large apartment building in the background is where James and Martha finally lived (photo c1940)

“Articles By Eric Gilroy”

Quick Contact

+44 (0)7557385501

Edge Dynamics, PO Box 673, Greenford, UB5 9SE, UK

Why Edge Dynamics?

We are passionate about honing straight razors to produce only the smoothest, sharpest edge possible. At Edge Dynamics, we offer you first-class, personal honing that includes all finishing touches and a properly stropped edge.

We Accept | PAYMENT OPTIONS